Prototype Lab/workshop

Protoype Lab/ Workshop

Photo: NTNU/Frøy Katrine Myrhol

Photo: NTNU/Frøy Katrine Myrhol

Machining Lab

Conventional mechanical workshop that is capable of performing most common operations on metals, plastics and composers.

The workshop has the following equipment:

- Lathe

- Milling machine (for steel)

- Milling Machine (foam, wood)

- Welding equipment (MIG/MAG, TIG, SMAW)

- Plasma torch

- Hydraulic press

- Grinding department (metal)

- Bomar Belt saw (metal)

Machining department for metal. Photo: NTNU/ Frøy Katrine Myrhol

Machining department for metal. Photo: NTNU/ Frøy Katrine MyrholMechanical Testing Laboratory

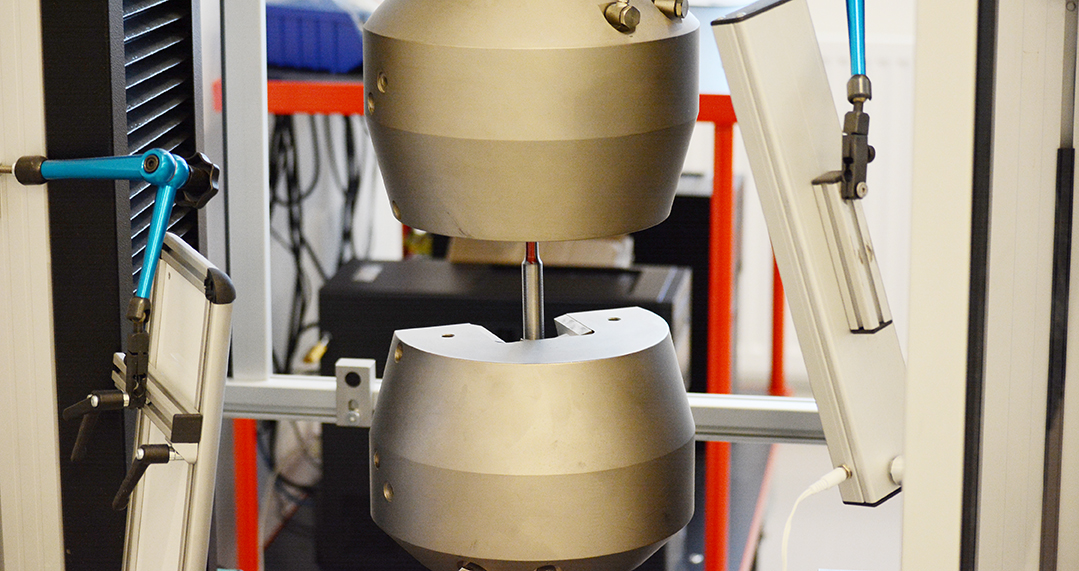

The Mechanical Testing lab contains equipment for testing material properties of different materials, primary metals and composites.

The laboratory has the following equipment:

- Wolpert tensile/compression testing machine, ± 600 kN

- Measuring of hardness number (Brinell, Vickers and Rockwell)

- Galdabini Universal Testing Machine, ± 200 kN

- Wolpert Charpy Testing Machine (steel and aluminum)

- Different microscopes and grinding equipment for macro test specimen

Galdabini Universal Testing Machine. Photo: NTNU/Frøy Katrine Myrhol

Galdabini Universal Testing Machine. Photo: NTNU/Frøy Katrine MyrholPlastic Lab

This laboratory is suitable for production of fiber reinforced plastic materials such as fiberglass, carbon and kevlar. It is also possible to produce smaller components with vacuum injection. The bachelor students do most of the activities in this laboratory.