Our area of research is the fabrication of functional thin films and interfaces. We are interested in studies on how strain, octahedral rotations, domains, geometric orientation, cation ordering, vacancies etc. can be used to design functional properties, and especially anisotropic properties. We are also interested in emergent phenomena on the interface, both between similar types of materials, like two oxides and dissimilar types of materials like an oxide and a 2D material, ceramics and metals and in different types of materials. The materials functional characterization is focused on magnetic, dielectric, piezoelectric and mechanical properties.

Our main methods for producing thin films are pulsed laser deposition and chemical solution deposition.

Reseach Interests

Geometric lattice engineering:

In epitaxial thin films, the film takes on the in-plane lattice parameters of the substrate. Hence one can control the structural features, and the functionality of the film by using different substrates, either with different lattice parameters or different orientations of the substrate. We are interested in using this to control and design different functional properties in our thin films. For example we use anisotropic strain to create active antiferromagnetic materials, strain to enhance piezoelectric response, and we use layer-by-layer controllability to design band gaps for intermediate band solar cells.

Interfaces between dissimilar materials:

At the interface between different materials one can get emergent behavior, i.e., functionality that neither of the materials have in bulk. We are interested in studying how different types of materials interact with each other on the interface. For example, on the interface between a magnetic oxide and a topological insulator, one can get dissipation-free spin currents. We are furthermore interested in the interface between ceramics, metals, and liquids. These are determined by complex diffusion, solubility and precipitation processes that influence material stability and functionality.

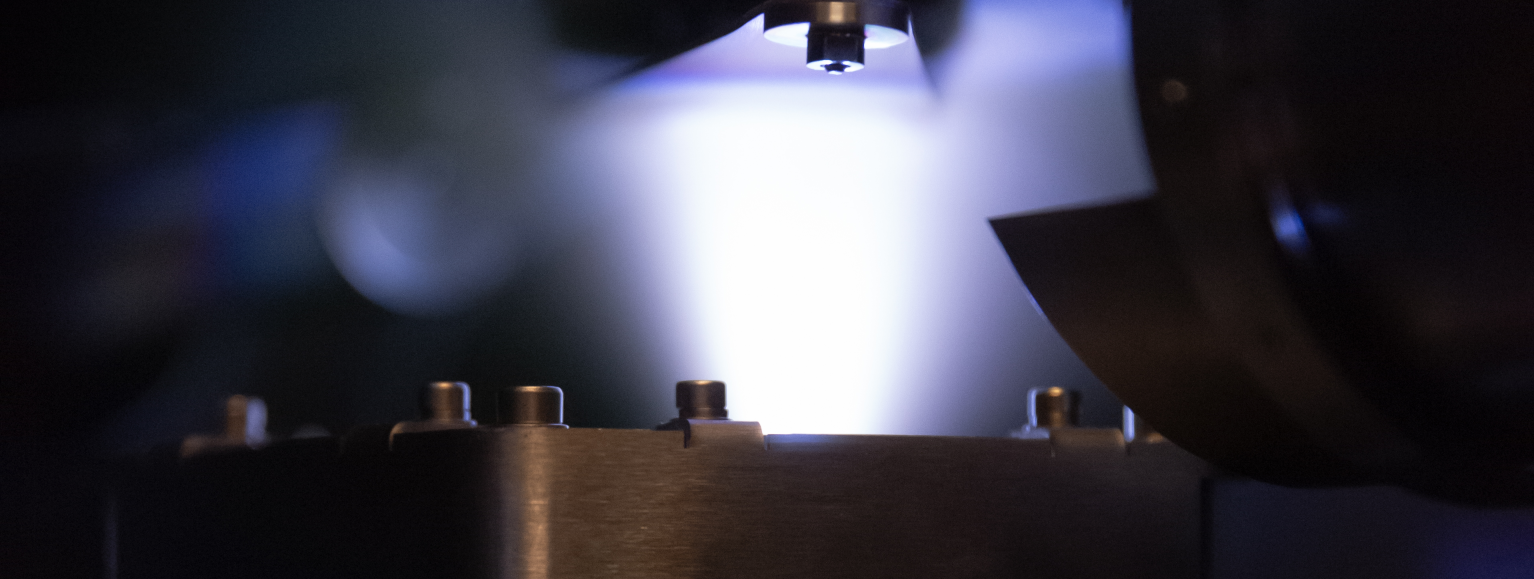

Pulsed laser deposition is our thin film technique with the highest precision. This is physical vapor deposition technique which is very versatile when it comes to materials, has precise stoichiometric control and layer-by-layer growth control, resulting in single crystalline epitaxial structures. In-situ RHEED monitors the growth and crystallinity.

Chemical solution deposition techniques are simple, low cost and result in polycrystalline, textured or epitaxial thin films.

We have developed an in-situ characterization platform for the studies of precursor deposition, nucleation, crystallization and orientation of thin films during the chemical solution deposition. The platform consists of synchrotron X-ray diffraction and infrared spectroscopy. Ex-situ film characterization is done by XRD, AFM, SEM as well as electrical and magnetic measurements.

V. H. Pedersen, A. B. Blichfeld, K. Bakken, D. Chernyshov, T. Grande and M.-A. Einarsrud

Crystallization and Texturing of SrxBa1–xNb2O6 Thin Films Prepared by Aqueous Solution Deposition─An In Situ X-ray Diffraction Study

Cryst. Growth Des. (2022)

K. Kjærnes, I. Hallsteinsen, R. V. Chopdekar, M. Moreau, T. Bolstad, I-H. Svenum, S. M. Selbach and T. Tybell

Uniaxial Néel vector control in perovskite oxide thin films by anisotropic strain engineering

Phys. Rev. B 103 (2021) 224435.

T. M. Raeder, T. S. Holstad, I.-E. Nylund, M.-A. Einarsrud, J. Glaum, D. Meier and T. Grande

Anisotropic in-plane dielectric and ferroelectric properties of tensile-strained BaTiO3 films with three different crystallographic orientations

AIP Adv. 11 (2021) 025016.

K. Bakken, A. B. Blichfeld, I.-E. Nylund, D. Chernyshov, J. Glaum, T. Grande and M.-A. Einarsrud

Controlling Phase Purity and Texture of K0.5Na0.5NbO3 Thin Films by Aqueous Chemical Solution Deposition

Materials 12 (2019) 2042.

E. Khomyakova, S. Wenner, K. Bakken, J. Schultheiß, T. Grande, J. Glaum and M.-A. Einarsrud

On the formation mechanism of Ba0.85Ca0.15Zr0.1Ti0.15O3 thin films by aqueous chemical solution deposition

J. Eur. Ceram. Soc. 40 (2020) 5376-5383.

K. Bakken, A. B. Blichfeld, I.-E. Nylund, D. Chernyshov, J. Glaum, T. Grande and M.-A. Einarsrud

Tailoring Preferential Orientation in BaTiO3-based Thin Films from Aqueous Chemical Solution Deposition

Chemistry-Methods (2021).

A. B. Blichfeld, K. Bakken, D. Chernyshov, J. Glaum, T. Grande and M.-A. Einarsrud

Experimental setup for high-temperature in situ studies of crystallization of thin films with atmosphere control

J. Synchrotron Radiat. 27 (2020).

K.-N. Pham, N. H. Gaukås, M. Morozov, T. Tybell, P. E. Vullum, T. Grande and M.-A. Einarsrud

Epitaxial K0.5Na0.5NbO3 thin films by aqueous chemical solution deposition

R. Soc. Open Sci. 6 (2019) 180989.