Thomas Alan Adams II

About

NTNU Projects: NTNU-MIT Energy Research Programme | Hydrogeni

NTNU Research Groups: Team Nuclear | Team Hydrogen | Process and Power Group

News: Paper on Risk of CO2 Avoided Published

Our third publication this year is a collaboration with colleagues who are specialists in risk and safety assessements for the process industry. In this work, PhD Student Federica Tamburini (University of Bologna) developed a new metric called the Risk of CO2 Avoided Index (RCAI). The purpose is to quantify the tradeoffs between the beneifits of a CO2-reducing technology with the increased risk to the personal safety of those who use it, live near it, or are otherwise affected by it.

For example, a government encourages or requires people to switch from fossil-powered to electric or hydrogen vehicles, what are the additional risks to their safety per tonne of CO2 avoided? How do these risks compare to other possible green technology options? Are the risks worth it?

In her study, Federica found that the increased risk to workers of a carbon capture system for a power plant was 0.017 fatalities per million tonnes of CO2 avoided, which is very roughly the emissions of a medium sized natural gas power plant per year. More research is needed to understand if these risks are high or low compared to other green technology options, like hydrogen-based systems.

You can read more through the link in the citation: Tamburini F, Cozzani V, Paltrinieri N, Adams TA II. Weighing risks against GHG reduction benefit in emerging green technologies. Canadian J Chem Eng (2025). https://doi.org/10.1002/cjce.25692

News: Paper on Dirty Plastics Recycling published

In the work, PhD Student Matthias Meier created conceptual designs of processes which convert dirty (unwashed, unsorted) plastics into fresh ethylene to create a way to recycle what cannot currently be recycled with conventional means. The processes uses gasification, reforming, methane synthesis, oxidative coupling of methane (ethylene synthesis), CCS, and distillation sections. He begins with the results of detailed, atomic-level gasification models by our colleague NTNU Prof. Corinna Schulze-Netzer to predict the various syngas compositions produced from gasification of various dirty plastics. Then he used this as inputs to Aspen Plus simulations of the full process to conduct environmental technoeconomic assessment (eTEAs) of the process in order to assess the quality of his designs, their costs, and their potential environmental benefits.

Matthias determined that his plastic waste to ethylene (PtE) process can recover 13-23% of the carbon in the plastic waste as fresh ethylene depending on the scenario. Each kg of PtE ethylene produced in this way avoids as much as 5.7 to 18.4 kg of CO2 compared to classic fossil-based ethylene depending on the design options, such as the use of CCS. With CCS enabled, the resulting costs of CO2 avoided is only 230 euro/tonne CO2 avoided, lower than most biofuels and a good number for the plasicts sector.

You can read more through the link in the citation: Maier M, Schulze-Netzer C, Adams TA II. Chemical recycling of plastic waste via production of ethylene from gasification syngas. Ind Eng Chem Res (2025). https://doi.org/10.1021/acs.iecr.4c03441

Other News: Systems and Control Transactions now recognized as Level 1 publication in Norway

Attention Norwegians! Systems and Control Transactions (SCT), an open access conference proceedings series published PSE Press, is now recognized at level 1 (Nivå 1) by the Direktoraet for høyere utdanning og kompetanse. So, you get publication points for the FOCAPD 2024 conference proceedings and upcoming ESCAPE 35 conference proceedings, both published in SCT. PSE Press, an imprint of the CAChE Foundation, a nonprofit dedicated to advancing computer-based chemical engineering research and education.

Exergy Tables is Out!

The latest textbook from my group will show you how to use thermo-mechanical and chemical exergy to analyze industrial and chemical process systems. Made for the practicing engineer, this book makes it easy with 3 simple chapters introducing the topic, and then 7 chapters packed full of tables and charts for thousands of chemicals, mixtures, fuels, and common process streams. We do the hard work for you, just look up the values you need and you are on your way. Order it from any bookstore today! See Exergy Tables – PSE Community.org

About the Group

The Adams research group is a leader in chemical engineering research that focuses on sustainable energy conversion systems, innovative chemical process design, and process systems engineering methodologies. We tackle major world issues related to chemical and energy systems, such as carbon dioxide capture, utilization and sequestration, power systems of the future, flexible chemicals production, mobile chemical technologies, synthetic fuels, alternative fuels, biofuels, renewable energy systems, nuclear energy, and many other areas of application. Prof. Adams’ team includes Postdocs, PhD students, masters students, and research associates.

Sustainable Solutions for a Changing World

My overall research goal is to make big impacts in the energy industry by creating the sustainable systems of the future that will significantly reduce greenhouse gas emissions. My team considers ways of converting energy sources such as natural gas, biomass, nuclear energy, wind, solar, coal, and petroleum into high-energy products such as electricity, transportation fuels, synthetic fuels, biofuels, alternative fuels, olefins, alcohols, and many others, all within the context of sustainability.

To do this, my team either creates innovative new chemical process systems out of existing technologies, or, creates new technologies that enable new systems. We synthesize sustainable chemical processes, create computer models of them, run simulations, and then perform technical, economic, and environ- mental analyses that yield critical information about the process and what role it can play in combating climate change. This is done in close collaboration with industrial or government stakeholders to identify high impact, practical solutions that are most likely to be commercialized and benefit society as a whole.

Core Methods and Techniques

- Process Systems Engineering

- Chemical Process Design and Process Synthesis

- Process Modeling & Simulation

- Process Optimization

- Process Dynamics

- Techno-economic Analyses

- Life Cycle Analyses & Environmental Impacts

- Unit Operation Design

- Energy Technology Valuation

Application Areas

- Industrial Energy Systems

- Gasification Technologies

- Coal / Petcoke / Biomass to Liquids and Fuels

- Gas to Liquids and Fuels

- Nuclear to Liquids and Fuels

- Advanced Power Plants

- CO2 Capture Systems

- Mobile Chemical Plants

- Systems Standardization

- Integrated Community Energy

- Steel Refinery Off Gas Handling

- Solid Oxide Fuel Cells

- Power-to-X

- Energy Storage

- Hydrogen and the Hydrogen Economy

- Agile & Flexible Chemical Manufacturing

- Semicontinuous Distillation

- Waste-to-Energy

- Concentrated Solar Thermal Power

Research

NTNU Projects: NTNU-MIT Energy Research Programme | Hydrogeni

NTNU Research Groups: Team Nuclear | Team Hydrogen | Process and Power Group

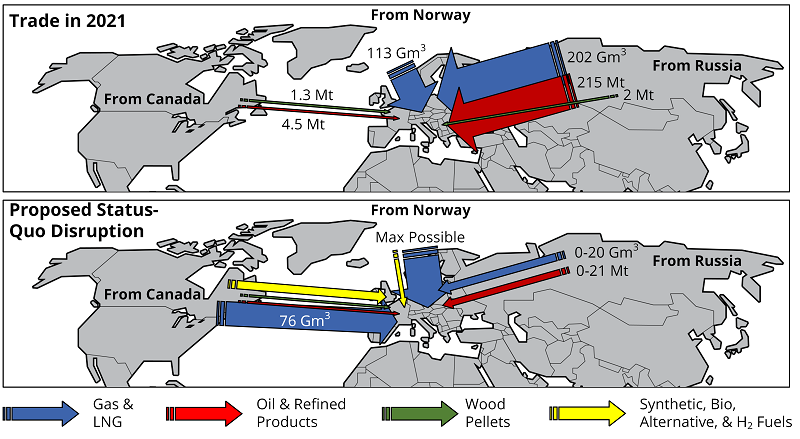

Building the Trans-Atlantic Energy Bridge

Displacing Russian energy will be one of Europe’s greatest challenges over the coming decade. Image from Adams, Canadian J Chem Eng 101:1729-1742 (2023)

Recent conflicts in Europe have exposed serious issues in the energy security of the Western world. Our overall goal is to develop a Trans-Atlantic Energy Bridge that will supply Europe with sustainable energy from North America. To do this, we need more sustainable forms of traditional fuels, but we can supplement this with alternative fuels, such as liquid hydrogen, biofuels, and synthetic fuels produced from wastes and nuclear energy.

We are developing the future energy conversion and management systems that will be key to transforming our global energy systems for a safer and more secure world, while maintaining carbon dioxide emissions reduction goals. The research includes sustainable design and eco-technoeconomic analysis of the unit operations, systems, and overall supply chain.

Selected Recent Publications

Adams TA II. How Canada can supply Europe with critical energy by creating a Trans-Atlantic Energy Bridge. Canadian J Chem Eng 101:1729-1742 (2023). Editor’s choice award. [Open Access]

Technologies for a Norwegian Hydrogen Economy

Data from Adams, Canadian J Chem Eng 101:1-13 (2023).

One of the hottest topics right now is the coming Hydrogen Economy. However, there are many concerns about the production, storage, and transportation of H2 fuel products. Our research looks at evaluating the most promising technologies from a triple-bottom-line of sustainability approach—what solutions have the best economic, environmental, and socio-political cases for adoption into the hydrogen economy? Which technologies, routes, and supply chains are the most promising? What are the best early-stage technologies to invest in? We answer these questions through bottom-up and top-down eco-technoeconomic analyses (eTEAs), often including the detailed design and simulation of candidate processes throughout the supply chain.

Some current technologies of interest include liquid hydrogen storage, formic acid as a hydrogen carrier, and solid oxide electrolysis systems.

Selected Recent Publications

Elrhoul D, Naveiro M, Gómez MR, Adams TA II. Thermo-economic analysis of green hydrogen production onboard LNG carriers through solid oxide electrolysis powered by organic Rankine cycles. Applied Energy 380:124996 (2025). [Open Access]

Naeini M, Cotton JS, Adams TA II. An Eco-Technoeconomic Analysis of Hydrogen Production Using Solid Oxide Electrolysis Cells that Accounts for Long-Term Degradation. Frontiers in Energy Research 10:1015465 (2022). [Open Access]

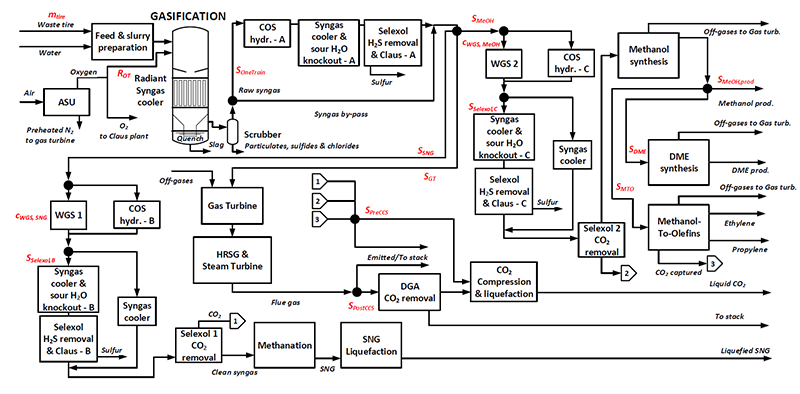

Waste-To-X Systems

This process superstructure shows the many different ways in which wastes can be converted into a variety of useful products through syngas routes. Image from Subramanian et al. Energy, 250:123722 (2022). [Download]

Waste can sometimes be a high energy resource that can be exploited for significant environmental benefits. Not only is the waste eliminated, but virgin resources (like fossil fuels) are displaced. In our group, we currently focus on dirty unsorted municipal plastics and spent rubber.

Through a gasification process at high temperature and pressure, the waste can be broken down into its atomic parts, which quickly recombine to for syngas, a mixture of CO, H2, and other gases. These can then be used to produce all sorts of products, like hydrogen fuels, synthetic natural gas, dimethyl ether, alcohols, activated carbon, or synthetic diesel/gasoline. Or, it can be combined with CO2 capture and used for clean power production. It is especially useful for producing fresh olefins (plastic precursors) for thermochemical recycling of waste plastics. Our group uses optimal design under uncertainty approaches to determine the best candidate processes and products under future market scenarios.

Selected Recent Publications

Meier M, Schulze-Netzer C, Adams TA II. Chemical recycling of plastic waste via production of ethylene from gasification syngas. Ind Eng Chem Res 64:1:575-589 (2025). [Publisher Version].

Fajimi LU, Oboirien BO, Adams TA II. Waste tire gasification process: A bibliometric analysis and comprehensive review. Fuel 368:131684 (2024) [Publisher Version]

Subramanian ASR, Kannan R, Holtorf F, Adams TA II, Gundersen TS, Barton PIB. Optimization under uncertainty of a hybrid waste tire and natural gas feedstock flexible polygeneration system using a decomposition algorithm. Energy 241:129222 (2023). [Publisher Version]

Subramanian ASR, Gundersen TS, Barton PIB, Adams TA II. Global optimization of a hybrid waste tire and natural gas feedstock polygeneration system. Energy 250:123722 (2022). [Publisher Version]

Fajimi LU, Oboirien BO, Adams TA II. Simulation studies on the co-production of syngas and activated carbon from waste tyre gasification process using different reactor configurations. Energy Conversion & Management X 11:1001005 (2021) [Open Access Version]

Subramanian A, Gundersen T, Adams TA II. Optimal design and operation of a waste tire feedstock polygeneration system. Energy 223:119990 (2021). [Publisher Version]

Okeke IJ, Adams TA II. Advanced Petroleum Coke Oxy-Combustion Power Generation with Carbon Capture and Sequestration: Part II: Environmental Assessment and Cost of CO2 Avoided. Canadian J Chem Eng 99:S340-S355 (2021). [Publisher Version]

Chemical Heat Pumps

This simple example of a chemical heat pump absorbs low temperature heat in the endothermic reactor and the reboiler, and discharges high temperature heat in the exothermic reactor. Image from Krishnadoss and Adams. Systems and Control Transactions, 3:484-482 (2024). [Download]

Chemical heat pumps upgrade low temperature waste heat into a high temperature heat product. They are similar in purpose to classic mechanical heat pumps, but use a very different mechanism. Low-temperature waste heat is absorbed through an endothermic, reversible chemical reaction, producing a high energy chemical or set of chemicals. The chemicals are separated and then the reaction is executed in reverse, releasing the stored energy, but at a much higher temperature. The primary advantage of a chemical heat pump over a mechanical heat pump are that chemical heat pumps are mostly powered by the low temperature waste heat and requires an order of magnitude less electricity consumption than mechanical heat pumps. In addition, the reversible reactions used in chemical heat pumps can be selected to achieve working temperatures or temperature lifts not possible in current commercial mechanical heat pumps.

Selected Recent Publications

Krisnadoss R, Adams TA II. Integration of a Chemical Heat Pump with a Post-combustion Carbon Capture Sorption Unit. Systems and Control Transactions 3:484-482 (2024) [Publisher Version]

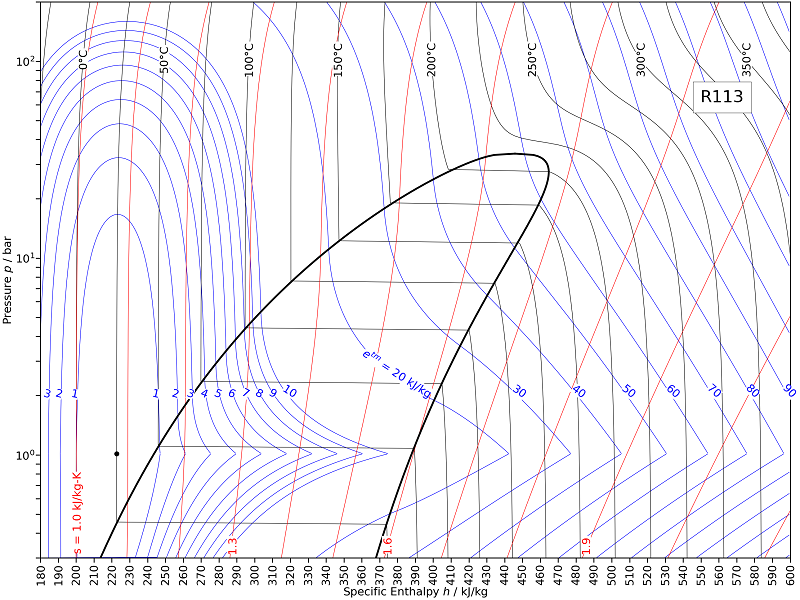

Exergy for Process Analyses

The a Pressure-Enthalpy-Exergy diagram for R113. Image from Adams and Gundersen., Ind Eng Chem Res 63:14:6286-6296 (2024) [full article]

Exergy is a thermodynamic property of energy and matter which is useful in the analysis of process systems. We use exergy analyses routinely to identify thermodynamic bounds on process capabilities, estimate quality of process performance, and also as a proxy for cost or value. Exergy research in our group has focused on the theory of exergy when applied to substances at low pressures (vacuum) and temperatures (approaching 0K). Our main contributions in this area are the generation of a new thermo-mechnical exergy equation for substances that works in vacuum conditions and identifying trends in exergy near 0K. We are extending our work in this area to environmental systems, using exergy as a proxy for pollution implications on water resources. Our book Exergy Tables brings exergy theory to the masses, making exergy analyses easy for the practising engineer.

Selected Recent Publications

Webinar: Exergy Analysis for Energy Systems. Computing and Systems Technology division of the American Institute of Chemical Engineers, hosted by APMonitor. (2024) [Watch Video]

Adams TA II. Exergy Examples for the Chemical Engineering Classroom. Systems and Control Transactions, in-press (2025).

Adams TA II. Thermo-Mechanical Exergy of a Substance in Cold Applications Approaching Absolute Zero. Systems and Control Transactions 3:2-9 (2024) [Publisher Version]

Adams TA II, Gundersen T. Thermo-Mechanical Exergy of a Substance Below Environmental Pressure Ind & Eng Chem Res 63:14:6286-6296 (2024). [Publisher Version]

Deng L, Adams TA II, Gundersen T. Exergy Tables McGraw-Hill Education (2023). ISBN: 9781264715725 [Textbook Page]

Eco-technoeconomic Analysis Standards Development

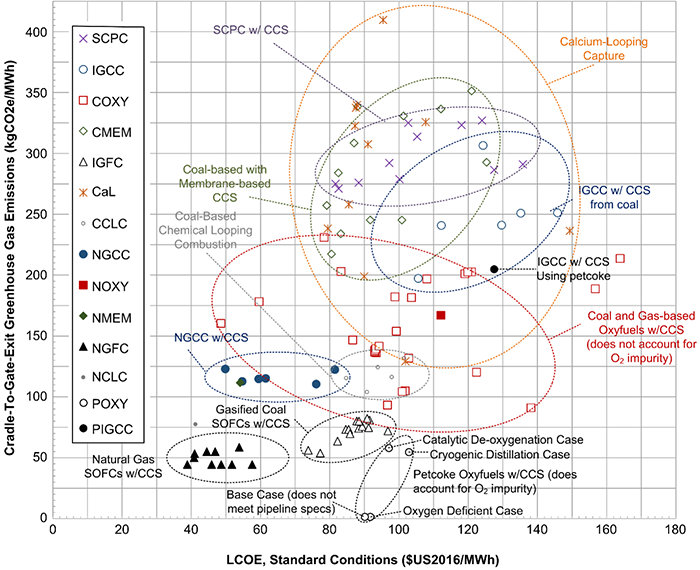

Our technology assessment meta study for advanced (future) power systems with CO2 capture technology. The study “de-hypes” the literature by recomputing key metrics such as life cycle greenhouse gas emissions and levelized cost of electricity (LCOE) according to a common set of analysis standards. This results in a clear and unbiased comparison between technologies, identifying the most and least promising for investment and research. The methodologies developed in this work are being incorporated into an ISO standard. Image from Okeke IJ, Ghantous T, Adams TA II. Chemical Product & Process Modelling, art. 41 (2021) [Download]

Our most common industrial collaborations are in the area of technology value assessments. We typically use eco-technoeconomic analyses (eTEAs) to evaluate the economic feasibility and environmental impacts of every new systems concept we put forward. We do this in order to understand our innovations in the context of the triple bottom line of sustainability. We also apply this for early technology screening of individual pieces of equipment. For example, our collaborators may have developed a new catalyst, membrane, reactor system, bioprocess, or separation technology. We then take that and try to assess its value by analyzing how the new technology would function in the context of the larger system. Typically, we need to design and simulate a new system that would incorporate the technology, and then use eTEAs to make judgements about the value of that technology compared to other competing strategies (which can result in similar or even very different systems). Some examples are:

- Solvent screening for biobutanol extraction

- Advanced power plants w/ CO2 capture

- Bio-butyl acrylate production

- Formic acid production

- Liquid H2 systems

- Seaweed as bio-feedstock

- Methanol to butanol conversion via acetic acid route

- Microwave-enhanced algae-derived lipid production

- Waste rubber-to-SNG

As a result of his work, Prof. Adams is now leading the efforts at the International Standards Organization as the Convenor in charge of the development of ISO TS 14076, the new global standard for conducting eTEAs which is based on the research methodologies developed by Prof. Adams.

Selected Recent Publications

Webinar: Techno-economic analysis and lifecycle assessment of emergying technologies in a circular economy. CircularChem Webinar Series. [Watch Video]

Glover M, Hoseinzadeh L, Adams TA II. Biomass-gas-and-nuclear-to-liquids (BGNTL) Polygeneration Process Part II: Techno-Economic Analysis. Canadian J Chem Eng, 100:2546-2556 (2022). [Publisher Version]

Okeke IJ, Adams TA II. Advanced Petroleum Coke Oxy-Combustion Power Generation with Carbon Capture and Sequestration: Part I: Design and Techno-Economic Analysis. Canadian J Chem Eng 2021:S323-S339 (2021). [Publisher Version]

Nezammahalleh H, Adams TA II, Ghanati F, Nosrati M, Shojaosadati SA. Techno-economic and environmental assessment of conceptually designed in situ lipid extraction process from microalgae. Algal Research 35:547-560 (2018) [Publisher Version]

Adams TA II, Hoseinzade L, Madabhushi PM, Okeke IJ. Comparison of CO2 capture approaches for fossil-based power generation: Review and meta-study. Processes 5:44 (2017) [Open Access Version]

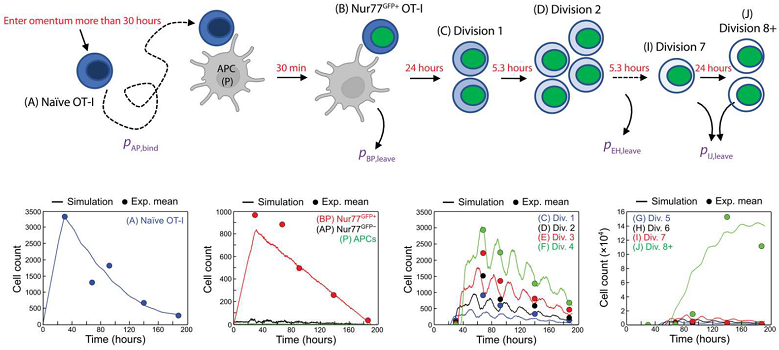

T-Cell Vaccine Development

We are developing systems for rapid vaccine candidate selection of the next generation of vaccines after mRNA: T-Cell vaccines. Here, our first principles models (lines) predict cyclic behaviour which explains the experimental data in the omentum in mice (circles). Image from Christian et al. Science Immunology 7, eabq7432 (2022). [Download]

Since 2019, we have been teaming up with immunologists, virologists, and pathologists to develop the next generation of vaccines called T-Cell vaccines. These promise to perform better against rapidly-mutating viruses like HIV and coronavirus. On a NIAID funded collaboration, we apply the same process dynamics principles to human and animal immune systems to aid in the development of the vaccines. We are developing a human model of how T-cells divide after a vaccine injection, which when combined with patient blood samples can be used to predict the future protective abilities of the shot.

Selected Recent Publications

Christian DA, Adams TA II, et al. cDC1 coordinate innate and adaptive responses in the omentum required for T cell priming and memory. Science Immunology 7, eabq7432 (2022). [Publisher Version | Open Access Version]

Douglas AC, Adams TA II, Christian DA. Dynamic modelling of T cell vaccination response. CSChE Systems & Control Transactions 1:6-10 (2021). [Publisher Version]

Risk and Water Impacts of CO2 Avoided

We want to know the extra risks to people's personal safety, impacts on upstream water supplies, and other unintended consequences arising from the adoption of green technologies. Image from Tamburini et al. Canadian J Chem Eng (2025). [Download]

We want to know the extra risks to people's personal safety, impacts on upstream water supplies, and other unintended consequences arising from the adoption of green technologies. Image from Tamburini et al. Canadian J Chem Eng (2025). [Download]

We are developing metric such as the Risk of CO2 Avoided and Water Impacts of CO2 Avoided that can help us understand the unintended negative consequences of adopting green technologies for the purposes of avoiding or abating greenhouse gas emissions. We collaborate with specialists in water pollution, safety, and risk, to understand and quantify the tradeo-ffs. For example, if you are going to adopt electric or hydrogen cars, build a CO2 pipeline through a community, or adopt wind and solar power with batteries, what are the additional personal safety risks to their health or life you asking people to take on who will be near these new technologies? What are the consequences on the water supplies in poor countries far up the supply chain where critical raw materials need to be mined?

Selected Recent Publications

Tamburini F, Cozzani V, Paltrinieri N, Adams TA II. Weighing risks against GHG reduction benefit in emerging green technologies. Canadian J Chem Eng, in-press (2025). [Publisher Version]

Moodley P, Harding K, Adams TA II. Assessing the undesired impacts on water sustainability from climate change mitigation technologies in fossil-based power generation. Environmental Science: Water Research and Technology 10:2509-2532 (2024). [Publisher Version | Open Access Version]

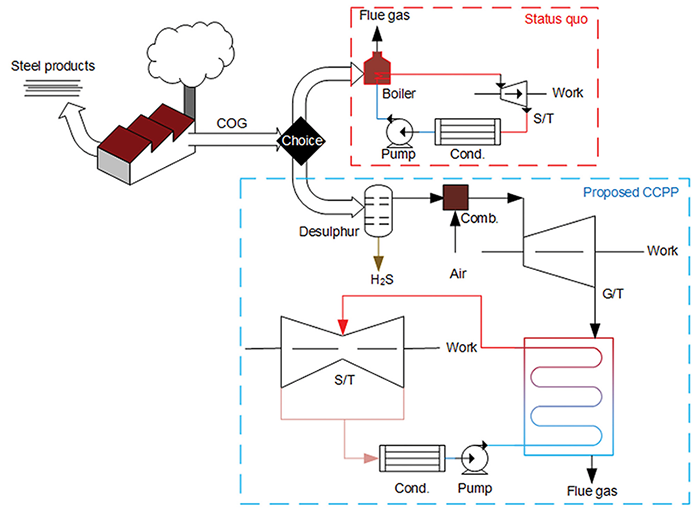

Steel Refinery Carbon Footprint Reduction

We designed an advanced combined cycle gas turbine system using coke oven gas (lower), displacing the current boiler-based steam turbine system. The system is in use today. Image from Deng L, Adams TA II. Ind Eng Chem Res, 57:38:12816-12828 (2018). [Publisher Version | Open Access Preprint]

In this collaborative project with ArcelorMittal Dofasco in Hamilton, we are creating processes that reduce the CO2 footprint of steel refining through process retrofits.

Avenue 1: We designed an advanced gas turbine based cycle powered by coke oven gas (COG) that can be retrofitted into place without the need for heat substitution elsewhere in the plant, resulting in the same direct CO2 emissions but a higher power production, thus reducing net CO2 emissions from the grid. This process has been constructed and now produces power from waste!

Avenue 2: We designed a process that captures CO2 from Blast Furnace Gas (BFG) and converts it to methanol, aided by advanced sulfur removal strategies. This both increases the potency of BFG for balance-of-plant uses and reduces direct CO2 emissions by “storing” carbon in methanol.

Avenue 3: We are designing systems to help displace coal with bio-char. We are focusing on valorizing the complex off-gases produced during bio-char production, noting that the mass of the off-gases is actually greater than the mass of the biochar produced.

Selected Recent Publications

Rose J, Adams TA II. Process Design and Techno-Economic Analysis of Usage of Biomass Pyrolysis By-Products in the Ontario and Aichi Steel Industries. Computer Aided Chemical Engineering 49:115-120 (2022) [Publisher Version]

Deng L, Adams TA II. Optimization of coke oven gas desulfurization and combined cycle power plant electricity generation. Ind Eng Chem Res, 57:38:12816-12828 (2018). [Publisher Version | Open Access Preprint]

Deng L, Adams TA II. TEA of Coke Oven Gas and Blast Furnace Gas to Methanol Process with Carbon Dioxide Capture and Utilization. Energy Conversion and Management 204:112315 (2020). [Publisher Version | Open Access Preprint]

Deng L, Adams TA II. Comparison of steel manufacturing off-gas utilization methods via life cycle analysis. Journal of Cleaner Prod 277:123568 (2020). [Publisher Version | Open Access Preprint]

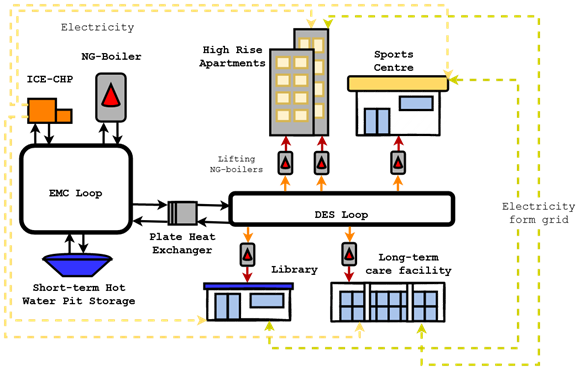

Integrated Community Energy Systems

An integrated community energy system (ICE) manages heat and electricity sharing between buildings in a neighbourhood. One’s waste becomes another’s energy source. Image from Monteiro, Cotton, and Adams, Cleaner Energy Production, 8:100118 (2024)

The energy systems of the future will be tightly integrated components that dispatch, share, and make energy on demand on increasingly localized networks. Energy harvesting from wind and solar will also play a major role. Significant energy savings and CO2 reductions can be achieved through integration, but this requires extremely complex dynamic system management, factoring in predictions, optimization, planning, and scheduling.

Selected Recent Publications

Monteiro NS, Cotton JS, Adams TA II. Design and eco-techno-economic analysis of a natural gas cogeneration energy management center (EMC) with short-term thermal storage. Cleaner Energy Systems 8:100118 (2024). [Open Access]

Semicontinuous Distillation Systems

![]()

A patent-pending system using divided wall semicontinuous distillation that fits in a shipping container. Image from Ballinger and Adams, Comput Chem Eng 105:197-211 (2017) [Download]

Semicontinuous distillation is an advanced form of distillation that has been developed by the Adams team over the past 17 years. The premise is that a single distillation column can be used to separate chemical mixtures that normally require two or three distillation columns to achieve. This is possible by the use of a complex design coupled with a custom control system that operates the column cyclically. Product is always withdrawn from the column, although in varying degrees throughout the cycle. Unlike batch though, there are no costly startup or shut-down phases in the cycle. The end result is a compact and cost effective system that is typically economically superior to traditional multicolumn designs at intermediate flow rates, especially those typical of biofuels and pharmaceutical manufacturing. The systems can be designed small enough to fit in a shipping container for remote deployment.

Selected Recent Publications

Aenugula SP, Chandrasekar A, Adams TA II, Mhaskar P. Minimizing Total Annualized Cost per tonne of feed processed of a Semicontinuous Distillation Process utilizing Data-driven Model Predictive Control. Comput Chem Eng, 186:108711 (2024) [Publisher Version].

Madabhushi PB, Adams TA II. On the application of shooting method for determining semicontinuous distillation limit cycles. Chemical Engineering Research & Design 160:370-382 (2020). [Publisher Version | Open Access Version]

Ballinger S, Adams TA II. Space-constrained purification of dimethyl ether through process intensification using semicontinuous dividing wall columns. Computers & Chemical Engineering 105:197-211 (2017) [Publisher Version | Open Access Version]

Carbon Capture, Utilization, or Sequestration (CCUS)

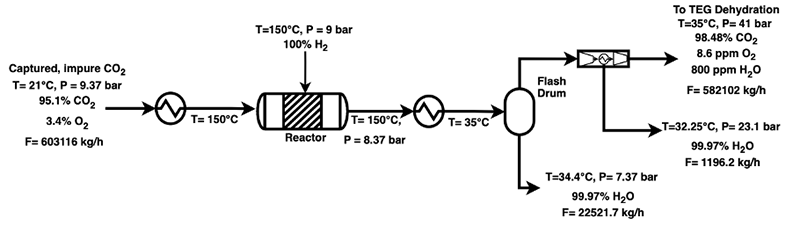

A catalytic CO2 purification process suitable for CO2 captured from oxycombustion power plants. Image from Okeke IJ, Ghantous T, Adams TA II. Chemical Product & Process Modelling, art. 41 (2021) [Download]

Although CCUS technologies are a part of most systems we study, we also research CCUS systems specifically. For example, we designed a CO2 purification system for oxyfuel combustion which outperforms other strategies, like cryogenic purification. We also develop CO2/water separation systems perfect for CCUS from solid oxide fuel cell, chemical looping, or oxyfuel power plants. We also designed nuclear-heated reactor systems that convert CO2 into syngas through high temperature mixed reforming or dry reforming.

Selected Recent Publications

Okeke IJ, Ghantous T, Adams TA II. Design Strategies for Oxy-Combustion Power Plant Captured CO2 Purification. Chemical Product & Process Modelling, art. 41 (2021) [Publisher Version]

Hoseinzade L, Adams TA II. Dynamic modeling of integrated mixed reforming and carbonless heat systems. Industrial & Engineering Chem Research 57:6013-6023 (2018) [Publisher Version | Open Access Preprint]

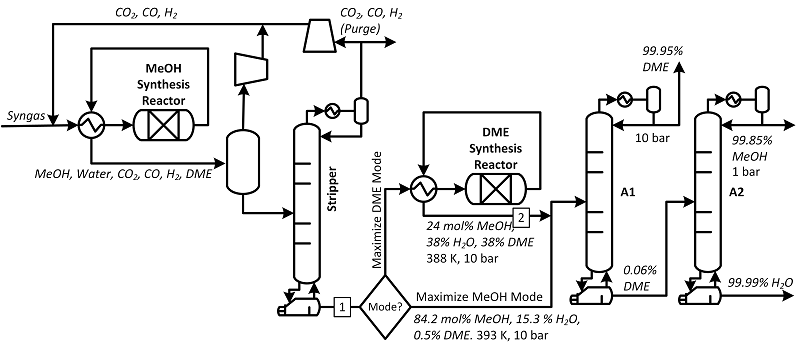

Flexible Systems and Agile Chemical Manfacturing

This flexible polygeneration process can transition between methanol product-ion and DME production depending on market and business conditions. Equipment is multi-purpose and used differently depending on the operating mode. Image from Adams et al. Frontiers Energy Res 6:41 (2018) [Download].

One major research focus in the Adams group is on flexible polygeneration, in which we create chemical plants which can change their product output mix based on market conditions. In this way chemical plants can be designed that are more robust in the face of market uncertainty and can respond to changing business or political circumstances. Our studies have shown that potentially up to an extra billion dollars in net present value can be earned in some cases by changing products along with prices and playing on the margins.

To do this, we combine chemical process synthesis and design expertise, process modeling and simulation, process intensification, techno-economic analyses, and optimization under uncertainty techniques. This produces probability-based economically optimal designs and corresponding strategies for its operation depending on the market conditions of the moment. Business case analyses are used to compute the added-value of the flexibility compared to a single-product baseline. Right now, we are working on flexible systems to produce bio-aviation fuels that can handle seasonal variations in harvested biomass sources.

Selected Recent Publications

Subramanian ASR, Kannan R, Holtorf F, Adams TA II, Gundersen TS, Barton PIB. Optimization under uncertainty of a hybrid waste tire and natural gas feedstock flexible polygeneration system using a decomposition algorithm. Energy 284:129222 (2023). [Publisher Version]

Subramanian ASR, Adams TA II, Gundersen T, Barton PIB. Optimal design and operation of flexible polygeneration systems using decomposition algorithms. Comput Aid Chem Eng 48:919-924 (2020) [Publisher Version]

Adams TA II, Thatho T, Le Feuvre MC, Swartz CLE. The optimal design of a distillation system for the flexible polygeneration of dimethyl ether and methanol under uncertainty. Frontiers in Energy Research 6:41 (2018). [Open Access Version]

Publications

To see my 150+ publications from prior positions at McMaster University, MIT, or University of Pennsylvania from 2005 to 2022, see my Google Scholar page

2025

-

Maier, Matthias;

Netzer, Corinna;

Adams Ii, Thomas Alan.

(2025)

Chemical Recycling of Plastic Waste via Production of Ethylene from Gasification Syngas.

Industrial & Engineering Chemistry Research

Academic article

-

Elrhoul, Doha;

Naveiro, Manuel;

Gómez, Manuel Romero;

Adams Ii, Thomas Alan.

(2025)

Thermo-economic analysis of green hydrogen production onboard LNG carriers through solid oxide electrolysis powered by organic Rankine cycles.

Applied Energy

Academic article

-

Tamburini, Federica;

Cozzani, Valerio;

Paltrinieri, Nicola;

Adams Ii, Thomas Alan.

(2025)

Weighing Risks against GHG Reduction Benefits in Emerging Green Technologies.

Canadian Journal of Chemical Engineering

Academic article

2024

-

Lewin, Daniel R.;

Adams Ii, Thomas Alan;

Bongartz, Dominik;

Léonard, Grégoire;

Mansouri, Seyed Soheil;

Martins, Fernando G..

(2024)

Teaching Process Design – Quo Vadis?.

Computer-aided chemical engineering

Academic article

-

Moodley, Prebantha;

Harding, Kevin;

Adams Ii, Thomas Alan.

(2024)

Assessing the undesired impacts on water sustainability from climate change mitigation technologies in fossil-based power generation.

Environmental Science: Water Research & Technology (ESWRT)

Academic article

-

Aenugula, Sakthi Prasanth;

Chandrasekar, Aswin;

Mhaskar, Prashant;

Adams Ii, Thomas Alan.

(2024)

Minimizing total annualized cost per tonne of feed processed of a semicontinuous distillation process utilizing data-driven model predictive control.

Computers and Chemical Engineering

Academic article

-

Adams Ii, Thomas Alan.

(2024)

Thermo-Mechanical Exergy of a Substance in Cold Applications Approaching Absolute Zero.

Systems and Control Transactions (SCT)

Academic article

-

Krishnadoss, Rajalakshmi;

Adams Ii, Thomas Alan.

(2024)

Integration of a Chemical Heat Pump with a Post-Combustion Carbon Capture Adsorption Unit.

Systems and Control Transactions (SCT)

Academic article

-

Adams Ii, Thomas Alan;

Gundersen, Truls.

(2024)

Thermo-Mechanical Exergy of a Substance Below Environmental Pressure.

Industrial & Engineering Chemistry Research

Academic article

-

Fajimi, Lanrewaju;

Oboirien, Bilainu;

Adams Ii, Thomas Alan.

(2024)

Waste tyre gasification Processes: A bibliometric Analysis and comprehensive review.

Fuel

Academic article

-

Monteiro, Nina;

Adams, Thomas Alan;

Cotton, James.

(2024)

Design and eco-technoeconomic analysis of a natural gas cogeneration energy management center (EMC) with short-term thermal storage.

Cleaner Energy Systems

Academic article

-

Ibric, Nidret;

Adams Ii, Thomas Alan;

Gundersen, Truls.

(2024)

Exergo-economic optimization of heat-integrated water networks.

Thermal Science and Engineering Progress

Academic article

2023

-

Rammohan Subramanian, Avinash Shankar;

Kannan, Rohit;

Holtorf, Flemming;

Adams, Thomas Alan;

Gundersen, Truls;

Barton, Paul I..

(2023)

Optimization under uncertainty of a hybrid waste tire and natural gas feedstock flexible polygeneration system using a decomposition algorithm.

Energy

Academic article

-

Ibric, Nidret;

Adams, Thomas Alan;

Gundersen, Truls.

(2023)

Synthesis of Heat-Integrated Water Networks with Exergo-economic Criteria.

Chemical Engineering Transactions

Academic article

-

Deng, Lingyan;

Adams, Thomas Alan;

Gundersen, Truls.

(2023)

Exergy Tables: A Comprehensive Set of Exergy Values to Streamline Energy Efficiency Analysis.

McGraw-Hill

McGraw-Hill

Textbook

-

Lai, Haoxiang;

Adams, Thomas Alan.

(2023)

Life cycle analyses of SOFC/gas turbine hybrid power plants accounting for long-term degradation effects.

Journal of Cleaner Production

Academic article

-

Lai, Haoxiang;

Adams, Thomas Alan.

(2023)

Eco-Technoeconomic Analyses of Natural Gas-Powered SOFC/GT Hybrid Plants Accounting for Long-Term Degradation Effects Via Pseudo-Steady-State Model Simulations.

Journal of Electrochemical Energy Conversion and Storage

Academic article

2022

-

Adams, Thomas Alan.

(2022)

Inflation- and Energy-Adjusted Historical Prices Reflect Disruptive Events to Global Energy Systems.

CSChE Systems and Control Transactions

Abstract

-

Adams, Thomas Alan.

(2022)

How Canada can supply Europe with critical energy by creating a Trans-Atlantic energy bridge.

Canadian Journal of Chemical Engineering

Academic article

Journal publications

-

Maier, Matthias;

Netzer, Corinna;

Adams Ii, Thomas Alan.

(2025)

Chemical Recycling of Plastic Waste via Production of Ethylene from Gasification Syngas.

Industrial & Engineering Chemistry Research

Academic article

-

Elrhoul, Doha;

Naveiro, Manuel;

Gómez, Manuel Romero;

Adams Ii, Thomas Alan.

(2025)

Thermo-economic analysis of green hydrogen production onboard LNG carriers through solid oxide electrolysis powered by organic Rankine cycles.

Applied Energy

Academic article

-

Tamburini, Federica;

Cozzani, Valerio;

Paltrinieri, Nicola;

Adams Ii, Thomas Alan.

(2025)

Weighing Risks against GHG Reduction Benefits in Emerging Green Technologies.

Canadian Journal of Chemical Engineering

Academic article

-

Lewin, Daniel R.;

Adams Ii, Thomas Alan;

Bongartz, Dominik;

Léonard, Grégoire;

Mansouri, Seyed Soheil;

Martins, Fernando G..

(2024)

Teaching Process Design – Quo Vadis?.

Computer-aided chemical engineering

Academic article

-

Moodley, Prebantha;

Harding, Kevin;

Adams Ii, Thomas Alan.

(2024)

Assessing the undesired impacts on water sustainability from climate change mitigation technologies in fossil-based power generation.

Environmental Science: Water Research & Technology (ESWRT)

Academic article

-

Aenugula, Sakthi Prasanth;

Chandrasekar, Aswin;

Mhaskar, Prashant;

Adams Ii, Thomas Alan.

(2024)

Minimizing total annualized cost per tonne of feed processed of a semicontinuous distillation process utilizing data-driven model predictive control.

Computers and Chemical Engineering

Academic article

-

Adams Ii, Thomas Alan.

(2024)

Thermo-Mechanical Exergy of a Substance in Cold Applications Approaching Absolute Zero.

Systems and Control Transactions (SCT)

Academic article

-

Krishnadoss, Rajalakshmi;

Adams Ii, Thomas Alan.

(2024)

Integration of a Chemical Heat Pump with a Post-Combustion Carbon Capture Adsorption Unit.

Systems and Control Transactions (SCT)

Academic article

-

Adams Ii, Thomas Alan;

Gundersen, Truls.

(2024)

Thermo-Mechanical Exergy of a Substance Below Environmental Pressure.

Industrial & Engineering Chemistry Research

Academic article

-

Fajimi, Lanrewaju;

Oboirien, Bilainu;

Adams Ii, Thomas Alan.

(2024)

Waste tyre gasification Processes: A bibliometric Analysis and comprehensive review.

Fuel

Academic article

-

Monteiro, Nina;

Adams, Thomas Alan;

Cotton, James.

(2024)

Design and eco-technoeconomic analysis of a natural gas cogeneration energy management center (EMC) with short-term thermal storage.

Cleaner Energy Systems

Academic article

-

Ibric, Nidret;

Adams Ii, Thomas Alan;

Gundersen, Truls.

(2024)

Exergo-economic optimization of heat-integrated water networks.

Thermal Science and Engineering Progress

Academic article

-

Rammohan Subramanian, Avinash Shankar;

Kannan, Rohit;

Holtorf, Flemming;

Adams, Thomas Alan;

Gundersen, Truls;

Barton, Paul I..

(2023)

Optimization under uncertainty of a hybrid waste tire and natural gas feedstock flexible polygeneration system using a decomposition algorithm.

Energy

Academic article

-

Ibric, Nidret;

Adams, Thomas Alan;

Gundersen, Truls.

(2023)

Synthesis of Heat-Integrated Water Networks with Exergo-economic Criteria.

Chemical Engineering Transactions

Academic article

-

Lai, Haoxiang;

Adams, Thomas Alan.

(2023)

Life cycle analyses of SOFC/gas turbine hybrid power plants accounting for long-term degradation effects.

Journal of Cleaner Production

Academic article

-

Lai, Haoxiang;

Adams, Thomas Alan.

(2023)

Eco-Technoeconomic Analyses of Natural Gas-Powered SOFC/GT Hybrid Plants Accounting for Long-Term Degradation Effects Via Pseudo-Steady-State Model Simulations.

Journal of Electrochemical Energy Conversion and Storage

Academic article

-

Adams, Thomas Alan.

(2022)

Inflation- and Energy-Adjusted Historical Prices Reflect Disruptive Events to Global Energy Systems.

CSChE Systems and Control Transactions

Abstract

-

Adams, Thomas Alan.

(2022)

How Canada can supply Europe with critical energy by creating a Trans-Atlantic energy bridge.

Canadian Journal of Chemical Engineering

Academic article

Books

-

Deng, Lingyan;

Adams, Thomas Alan;

Gundersen, Truls.

(2023)

Exergy Tables: A Comprehensive Set of Exergy Values to Streamline Energy Efficiency Analysis.

McGraw-Hill

McGraw-Hill

Textbook

Teaching

Courses

Outreach

Research Brochure

Exergy Tables

Learn Aspen Plus in 24 Hours

Colossal Machines

YouTube Channel

LAPSE

2024

-

PosterLitleskare, Mira Elise; Pokhrel, Basanta Raj; Oleinikova, Irina; Adams Ii, Thomas Alan. (2024) Techno-Economic Analysis of Green Hydrogen Production from PV Plants. FME HYDROGENi H2Science , Trondheim 2024-06-18 - 2024-06-19