Modelling - ComKin

Modelling

Modelling

Detailed modelling of particle reactivity in turbulent combustion

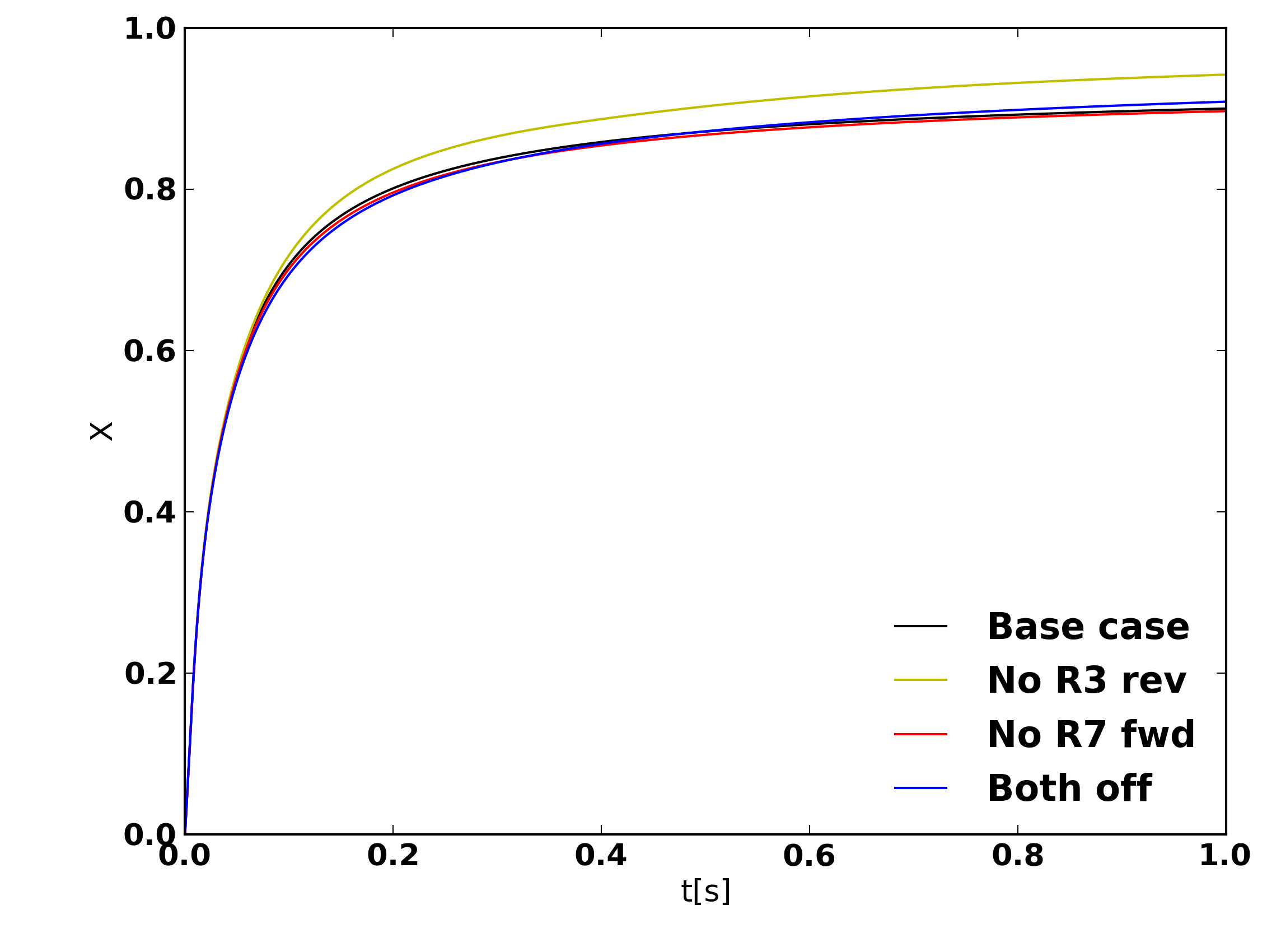

Coal conversion over time

Coal conversion over timeThis work is part of the Cenbio project of NTNU and SINTEF.

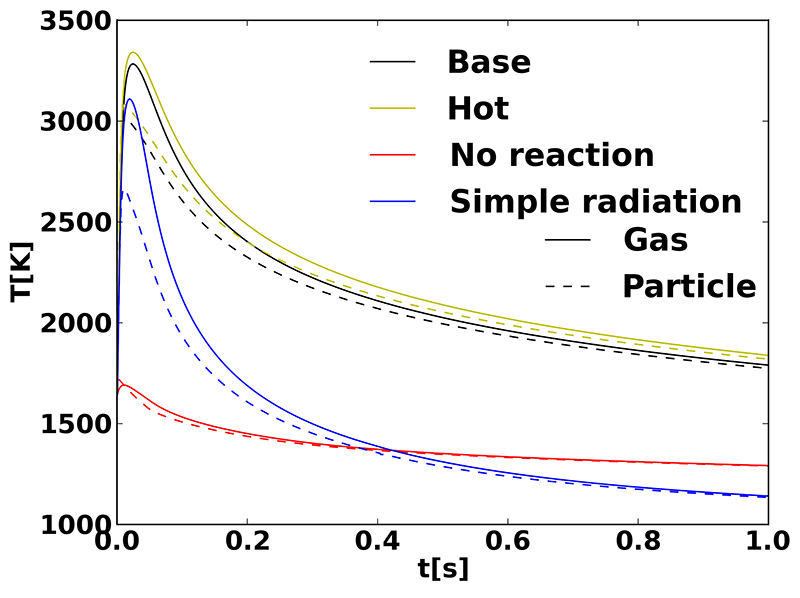

Particle and gas temperature over time

Particle and gas temperature over timeParticipants:

Jonas Krüger (NTNU)

Terese Løvås (NTNU)

Nils Erland L. Haugen (SINTEF Energy Research)

Low-NOx combustion technology (Numerical part)

Combustion of hydrogen-rich fuels, such as syngas, have received increasingly attention in the context of climate change and the urgent need for alternative fuels. Syngas with high hydrogen levels and maximal relative concentrations of the carbon species as CO2 is particularly interesting for carbon capture and storage (CCS), which eliminates or at least minimizes CO2 emissions. One technology that can provide such gas and remove CO2 fromthefuel mixture is pre-combustion CCS. On the other hand, the high reactivity and combustion temperature of the remaining hydrogen-rich fuel generates harmful and regulated mono-nitrogen oxides (NOx) during combustion. Reduction NOx emissions is therefore a major topic in combustion research. Low NOx burners designed for natural gas can, however, not be operated safely with hydrogen-rich fuels, due to the significand different transport properties of hydrogen, which have a strong impact on the likelihood of flashbacks.

These challenges led to the development of a patented low NOx burner at the department of Energy and Process Engineering at NTNU and SINTEF. The burner features a conical frustum shaped bluff body generating a flame stabilizing recirculation zone. Fuel is injected into an accelerated crossflow to restrict the potential for flashback. The fuel and air is partially premixed before reaching the combustion zone. The burner has proven good emission performance at laboratory scale. However, the scalability of the system to prototype/industrial size is not well understood yet. A numerical model of the burner is therefore currently been build up making a detailed analysis of the burner flow characteristics accessible. Different turbulence and combustion models as well as other sub-models have been employed and validated against experimental data aiming for a numerical model that is capable to describe the burner characteristics sufficiently. Based on the insight in the burner dynamics gained from the numerical simulations a scaling attempt can be made.

Participants:

Christoph Meraner (NTNU)

Terese Løvås (NTNU)

Numerical simulations in Biofuel and engine applications

The numerical tools are provided by a collaborating partner LOGE.

Participants:

David Emberson (NTNU)

Terese Løvås (NTNU)

CFD−DPM/DEM Simulation of Multiphase Reacting Flow

An example of CFD-DEM simulation of biomass gasification with steam in a fluidized bed reactor (click on the image for the full paper)

An example of CFD-DPM modeling of biomass gasification behavior in an entrained-flow reactor (click on the image for the full paper)

Participants:

Tian Li (NTNU)

Terese Løvås (NTNU)