Experimental Research - ComKin

Experimental research

Experimental research

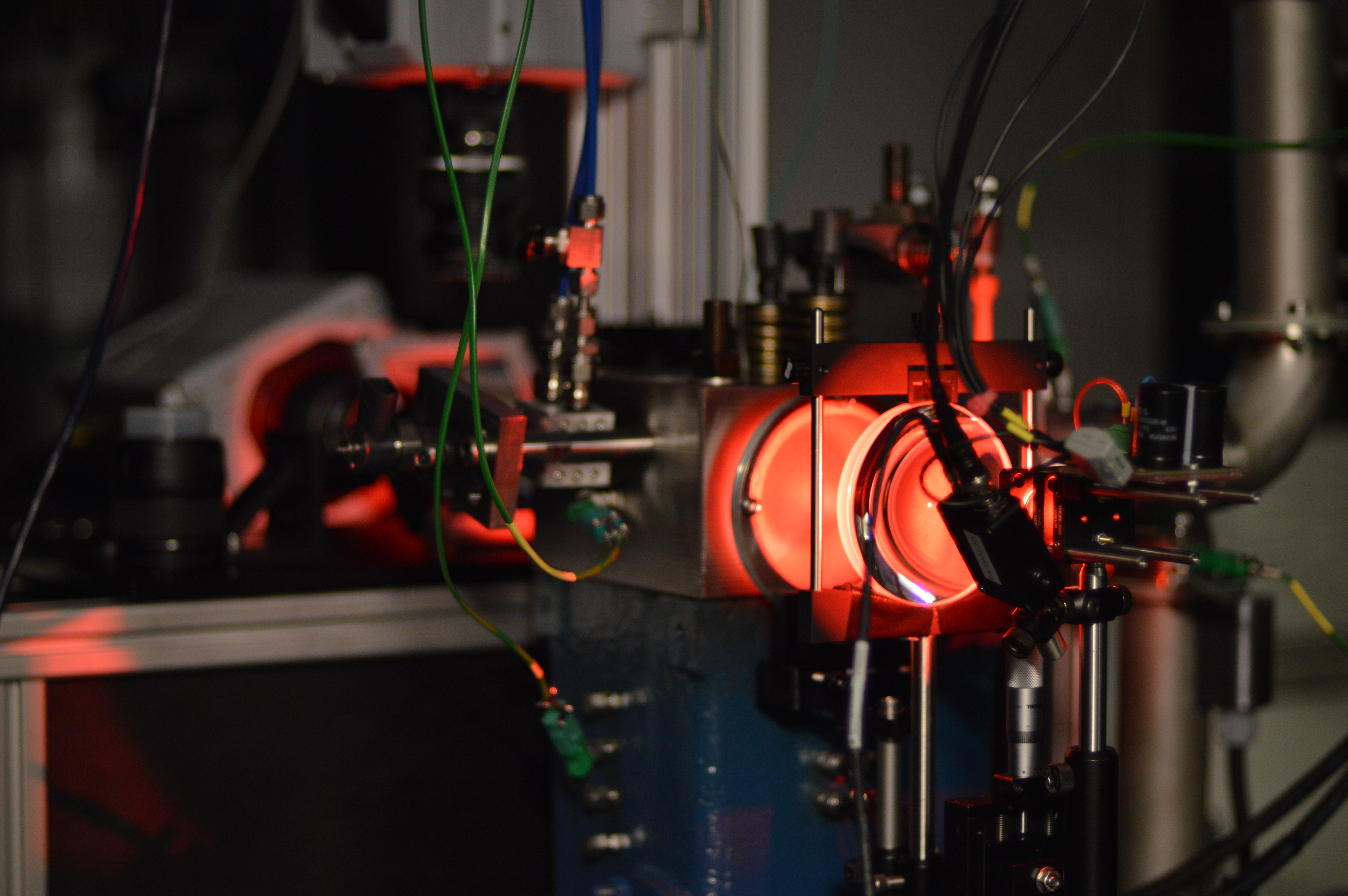

In flame soot production and OH* emission for a typical Diesel fuel injection spray flame

In flame soot production and OH* emission for a typical Diesel fuel injection spray flameAlternative fuels for internal combustion engines

The implementation of new, alternative fuels for internal combustion engines is identified as great importance in reducing global CO2 emissions and reducing harmful local emissions. Whilst there is a great drive for electrification of the automotive sector, it is agreed that there are many applications that internal combustion engines will remain the primary source of motive power for many years to come. These include larger compression engines found in trucks or off highway application, power generation and shipping.Biofuels are widely used, either on their own or blended with conventional fuel. Questions over their ability to fully mitigate CO2 persist, as well as their impact on land use and food competition. These concerns are driving the research and development of so called 2nd generation biofuels, made from non-food crops grown on marginal land or waste.

2nd generation biofuels should significantly reduce competition with food producing agriculture and reduce greenhouse gas emission (GHG) along with well-to-wheel energy efficiency. With recent developments in the legislative framework and society at large, there is greater scrutiny than ever on local harmful emissions, most notably soot and nitrogen oxides. It is imperative that any new fuels developed must, at a minimum, not make these emissions worse and ideally should aid in the mitigation of these local emissions.

The work conducted in the MotorLab is primarily concerned with developing and testing new fuels in a compression ignition type engine. In conjunction with the numerical work conducted in the group, the lab is also used to examine possible chemical surrogates that may be used to provide a simplified model for combustion of diesel fuel and biodiesel type fuels. Due to the complex nature of the multi-phase dynamics of spray combustion present in a compression ignition engine, the lab is also capable of examining fuel injection sprays.

Diffused Backlit Illumination system on Optically Accessible Compression Igntion Combustion Chamber (OACIC)

Diffused Backlit Illumination system on Optically Accessible Compression Igntion Combustion Chamber (OACIC)1. A fully instrumented, large automotive (3,2 liter) compression ignition engine. The engine is fitted with Horiba gas analyzer and Cambustion DMS 5000 to give a full emission spectrum for any new fuel. The engine is fitted with control system that allows user control of much of the engines operation. All manufacturer emission controls are removed, and simplified injection strategies are used to highlight the fuels influence. The engine is also fitted with sampling ports that allow collection soot for examination in a TEM and TGA.

2. An optically accessible compression ignition combustion chamber (OACIC), consisting of a modified cylinder head on top of a large bore single cylinder engine. Sing high speed cameras and image intensifiers with high power LED illumination systems, in flame soot and ignition character is examined.

3. High pressure fuel injection chamber.

Currently the lab is working though a campaign examining biofuel surrogate fuels, fuel additives to reduce harmful emissions, soot characterization and collection techniques and alternative fuels for the future.

The work is part of the following international collaborative projects: Bio4Fuels

Contact: David Emberson

Thermochemical conversion of biomass at high temperature and high heating rate conditions

SEM images of parent fuel particles and corresponding char produced at high heating rate

SEM images of parent fuel particles and corresponding char produced at high heating rate

Thermochemical conversion of biomass, such as combustion and gasification, is a complex process. Primarily, it consists of two partially overlapping steps: (1) pyrolysis of biomass to produce volatiles and solid char, and (2) conversion of the volatiles and solid char. A collaboration study between NTNU, SINTEF Energy Research, and Sandia National Laboratories (USA) has been conducted in order to better understand both of those two steps. Experiments regarding to devolatilization of biomass and coversion of char have been carried out by using an entrained flow reactor at high temperature and high heating rate conditions. Experimental data were interpreted by aid of CFD analysis and multiple characterization methods.

This work was carried out within the GasBio project, funded by Research Council of Norway and industry partners.

Participants:

Tian Li (NTNU)

Terese Løvås (NTNU)

Liang Wang (SINTEF Energy Research)

Christopher Shaddix (Sandia National Laboratories)

Low-NOx combustion technology (Experimental part)

The project focuses on the study of a laboratory-scale low-NOx burner. Design of experiments technique is applied in order to effectively explore relationships between burner operation settings and NOx emissions. The measurements involve various methods based on advanced gas analyzers and laser-based techniques such as particle imaging velocimetry in order to understand flow field in the burner and its impact on nitrogen oxides formation.

Participants:

Terese Løvås (NTNU)

Mario Ditaranto (SINTEF Energy Research)