NTNU NanoLab

NTNU NanoLab

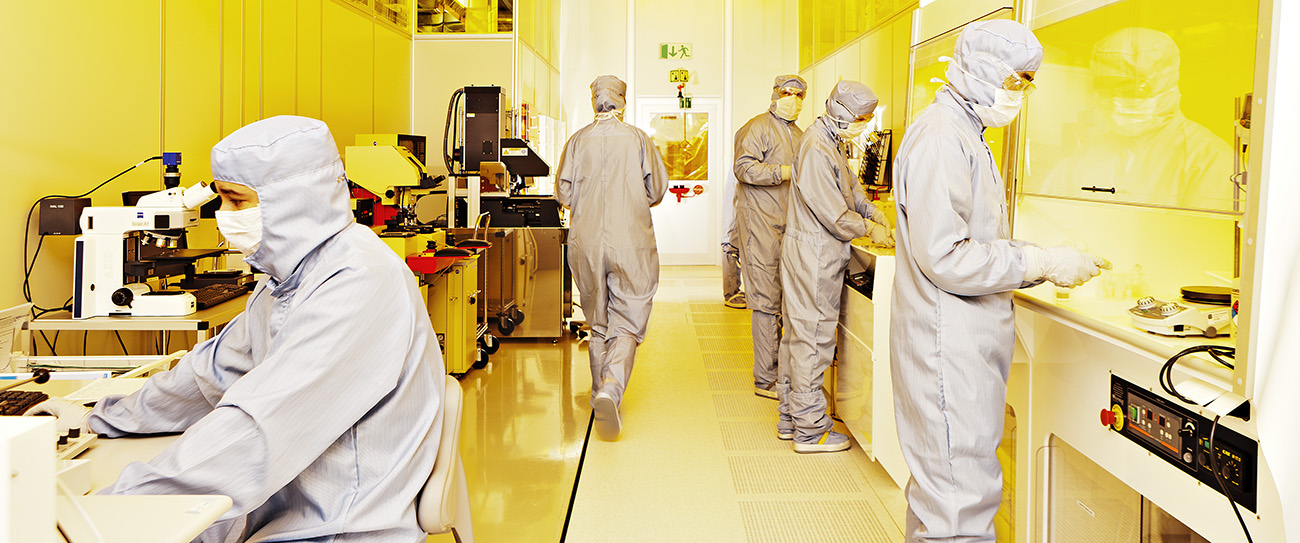

NTNU NanoLab is one of four cleanrooms within the national infrastructure, "The Norwegian Micro- and Nanofabrication Facility", NorFab. The facility is open for students and scientists at NTNU, as well as external researchers and start-up companies.

NTNU NanoLab is run by a staff of 9 engineers and operated according to hands-on principles. The infrastructure has a 700 m2 cleanroom with cleanliness ranging from ISO7 to ISO5 and vibration reduced zones at VCF-level. The cleanroom is also built according to GMO laboratory class 2 requirements.

Vacant positions

PhD position - in Physics and Nanotechnology(Deadline 23.11.2025)

PhD position - in Physics and Nanotechnology(Deadline 23.11.2025)

This PhD position is within the field of experimental materials physics and nanotechnology, in the project «Nanoscale imaging of magnetic skyrmion dynamics in thin film devices» (NIMSKY). Magnetic skyrmions are nanoscale stable magnetic quasiparticles which move when a current is applied. This process requires very little electrical power, which makes skyrmion devices contenders for future low-power computation. However, due to their small size and magnetic nature, skyrmions are difficult to image, especially while moving due to an electric current.

The aim is to both generate and study such magnetic skyrmions, by depositing nanostructured thin film materials and then making highly customizable in-situ chips using the back etching technique at NTNU NanoLab. These chips will then be used to perform in-situ magnetic nanocharacterization at the Trondheim Node of NORTEM – the national infrastructure for advanced Transmission Electron Microscopy (TEM). The ultimate goal is to perform in-operando studies in the TEM on functioning nanostructured skyrmion thin film devices.

Cleanroom information

- Access to NTNU NanoLab

- Technologies and equipment

(NorFab web page) - Courses

- Prices (pricelist on NorFab web page)

- Support (NorFab web page)

Events

Official launch of CC-NorChip

Official launch of CC-NorChip

November 13, 2025, at 10.00 – 16.00, at Oslo Science Park, "Toppsenteret"

The main objective of CC-NorChip is to strengthen the competitiveness, innovation, and technological leadership of Norwegian and European companies.

The program will include presentations on:

• The strategic importance of semiconductor, sensor and quantum technologies

• How CC-NorChip will contribute to the ecosystem in Norway through services

• The opportunities inherent in the EU and the Chips JU program

Among our speakers you will find:

• Minister of Digitalization and Public Administration Karianne Oldernes Tung (Ap)

• Nordic Semiconductor

• Kongsberg Discovery; Anders Rønningen, Executive Vice President Seatex

• Sonitor; Maaike Taklo, VP Engineering

• Imec, EU Chips Design Platform; Denis Villers, Program Manager

• The Research Council of Norway; Liv Furuberg, Special Advisor

• Innovation Norway; Steinar Brede, Special Advisor

Participation is free of charge. Please register here by 13.00 on November 10, 2025

Particle Engineering Days 2025

Particle Engineering Days 2025

December 8–9 at Scandic Lerkendal, Trondheim.

This annual meeting will showcase cutting-edge research activities in the areas of Nanomedicine, Colloids and Interfaces, Hydrometallurgy & Battery Recycling, and Environmental Applications.

The two-day program will include:

• Invited lectures from national and international experts across academia and industry

• Research talks by PhD candidates and Master’s students within PEC

• Interactive poster sessions

Registration is free and open to all! Please here before 23rd November.

NTNU NanoLab leads the national infrastructure NorFab

NTNU NanoLab is part of the Nordic Nanolab Network

NTNU NanoLab is part of the European Nanolab Network.